PBU Panel

Similar to a U Panel, the PBU panel offers excellent performance and a clean visual appeal

Home » Metal Panel Systems » Exposed Fastener Panels » PBU Panel

Performance and Versatility: PBU panel

Our PBU panel is known for its reliability and performance in the construction industry, particularly in the demanding climates of Texas and other southern regions. With its exposed fastening system, the PBU panel has garnered a reputation for performance at a competitive price point.

Unmatched Performance-Price Ratio

PBU is hailed as the top choice among exposed metal panel systems in the United States, thanks to its remarkable balance of performance and affordability. This makes it a preferred option for both residential and commercial projects, offering unparalleled value without compromising on quality.

Flexibility for Installation Crews

One of the standout features of the PBU panel is its versatility, providing installation crews with the flexibility they need to execute projects efficiently. Whether it’s a residential renovation or a large-scale commercial development, the PBU panel adapts seamlessly to diverse installation requirements.

The exposed fasteners incorporated into the PBU panel design ensure robust weather protection, provided proper maintenance is upheld. This makes it a dependable choice for projects in regions prone to extreme weather conditions, offering peace of mind to both installers and property owners.

Enhanced Aesthetic Appeal

In addition to its functional benefits, the PBU panel boasts a sleek and contemporary appearance that enhances the visual appeal of any structure. Its lower profile and softer aesthetic distinguish it from traditional R panels, allowing designers to achieve modern architectural visions with ease.

Versatile Installation Options

The PBU panel’s versatility extends to its installation options, as it can be effortlessly installed both vertically and horizontally on walls. Whether it’s used as a liner panel, partition wall, or as a standalone architectural feature, the PBU panel delivers exceptional results across diverse applications.

Designed as through-fastened panels, the PBU panels offer seamless integration into construction projects. They can be installed directly over purlins or joists, streamlining the installation process and minimizing downtime on the job site.

Panel Features

Panel Features Include:

- 26 gauge steel (standard)

- 29 gauge steel (optional)

- 24 gauge steel (optional)

- Substrate Materials:

- Galvalume (standard)

- Galvanized (optional)

- Colors available on standard, premium and metallic.

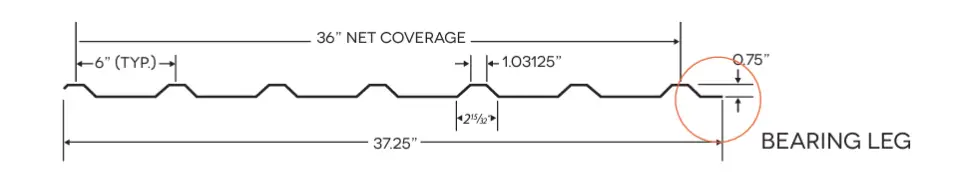

- Rib Spacing: 6″ O.C.

- Rib Height: ¾”

Testing & Performance

Panel Certifications Include:

- UL Construction Number: TGKX.39

- Uplift resistance of prepared roof-covering materials

- UL 580 Class90.

- Impact resistance of prepared roof-covering materials

- UL2218 Class 4.

- Fire tests of roof coverings

- UL 790.

- Class A, B, C. External fire exposure.

- TDI Texas Approved

Get a Quote

Panel Details

Panel Profile

Panel Enviroments

PBU Panel is suitable for use on the following environments:

- Extreme High Temperatures

- Low Temperatures (Freeze/Thaw)

- High Wind Environments

- Hail Prone Regions

- Fire Prone Regions

Building Locations

PBU Panel is suitable for use on the following building locations:

- Roofing

- Siding

- Ceiling

- Soffit

- Interiors

Finished Coverage

- Roof: 29.33″ Finished Coverage

- Wall: 32″ Finished Coverage

Panel Variations

- PBU Panel is not currently offered with variations differing from the original panel profile.

For custom panel designs, please contact a helpful team member

Panel Gauges

- Standard Thickness: 26 gauge steel

- Optional Thickness: 24 gauge steel*

- Optional Thickness: 29 gauge steel*

*Longer lead times may apply

Fastener Options

- Exposed, through-fastened screws

Panel Length

PBU Panel is not available for on-site roll-forming. The max panel length is determined by the length of the trailer which varies depending on state.

- Max Length, Texas: 53′ panels

Rib Height(s)

- 3/4″ Rib Height

Recommended Roof Slope

Minimum slope varies based on potential for ice & snow build up:

- No risk of ice & snow: 1:12 w/ mastic

- Potential risk of ice & snow: 2:12 w/ mastic

Paint Warranties

- PVDF – 40 year

- SMP – 40 year

- Acrylic – 40 year

- Bare Galvalume – 25 year

Panel Documentation

Trim Details

Specification Guide

Installation Guide

Looking for Additional Information?

Still have a question about this or other panels? Check out our range of articles on metal roofing, siding, coils & flats, and other industry information below.

Looking for more information?

Check out our range of articles on metal roofing, siding, and other industry information.