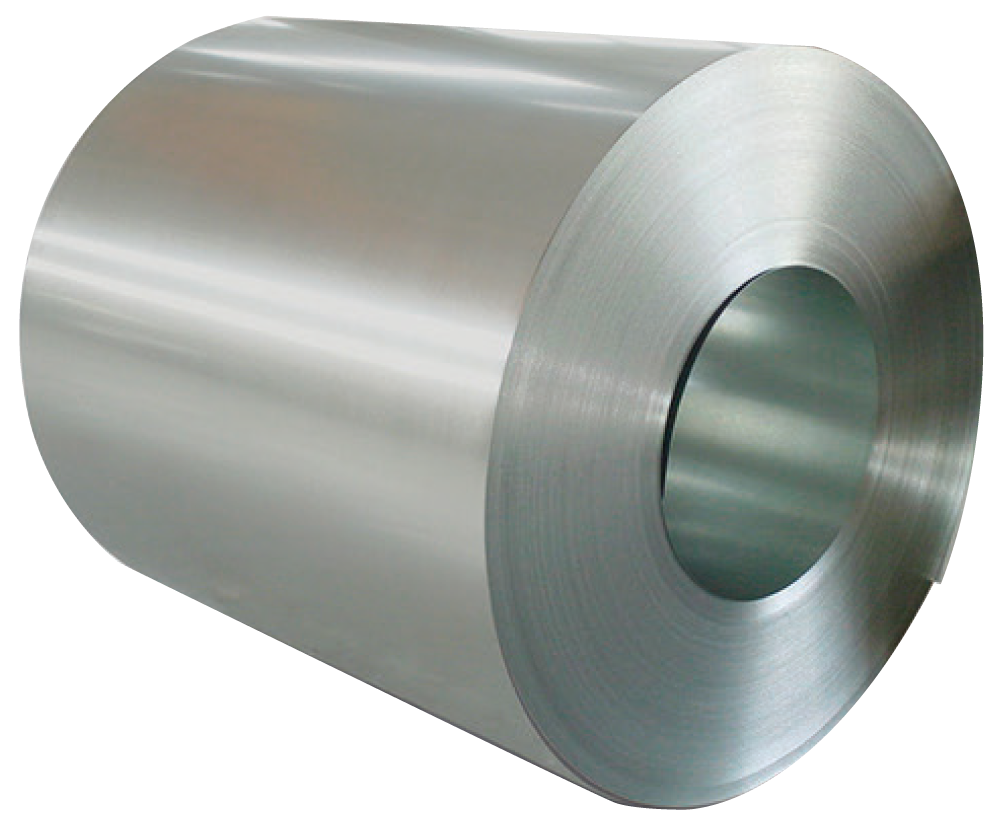

Hot-dipped galvanized commercial steel is a carbon steel sheet coated with zinc on both sides through a continuous hot-dip process. This method forms a durable iron-zinc alloy bond, providing excellent corrosion resistance and long-lasting performance.

Galvanized steel is among the most economical options for corrosion-resistant sheet metal and is well-suited for a wide range of architectural, industrial, and fabrication applications. It can be roll-formed, brake-formed, lock-seamed, riveted, spot-welded, or soldered.

Coating weight is measured in ounces per square foot.

Designation G-90 indicates a minimum of 0.90 oz/ft² of zinc coating,

applied equally on both sides of the sheet for enhanced protection against corrosion.

ASTM A924: Governs general requirements for carbon steel sheet metal coated by the hot-dip process, including tolerances on thickness, width, camber, and shape.

ASTM A653: Covers requirements for the galvanized coating, including chemistry, mechanical properties, and coating weights for various grades.

Ideal for architectural, industrial, and general-purpose applications.

Hot-dipped galvanized commercial steel is a carbon steel sheet coated with zinc on both sides through a continuous hot-dip process. This method forms a durable iron-zinc alloy bond, providing excellent corrosion resistance and long-lasting performance.

Galvanized steel is among the most economical options for corrosion-resistant sheet metal and is well-suited for a wide range of architectural, industrial, and fabrication applications. It can be roll-formed, brake-formed, lock-seamed, riveted, spot welded, or soldered.

Ready to experience the Quality Metals difference? Get in touch today for a quote, consultation, or custom order.

Quality Metals supports builders, contractors, and installers throughout the U.S. with environmentally safe manufactured metal panel systems, metal coils, flats, building kits, and perimeter edge solutions.